Understanding Injection Molding Prototypes

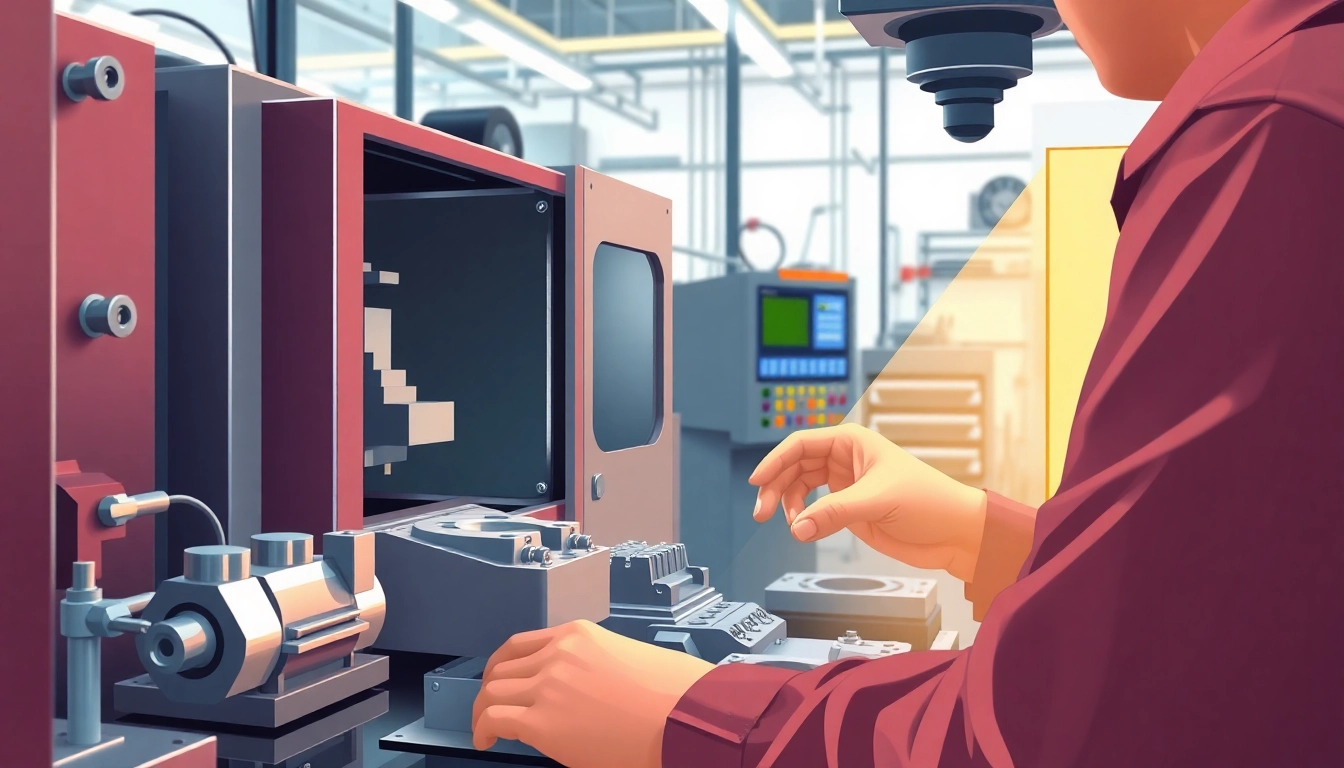

Definition and Purpose

Injection molding prototypes are preliminary models created using the injection molding process, which allows manufacturers to assess design function and feasibility before proceeding to full-scale production. This method is particularly valuable in industries such as automotive, consumer goods, and electronics, where the precision and functionality of parts are critical.

The main purpose of creating injection molding prototypes is to validate designs and identify any potential issues early in the development process. This proactive approach can save significant time and resources, as redesigning a prototype is often more manageable than addressing errors found during large-scale manufacturing. By using injection molding prototypes, companies can ensure their products meet quality standards and function as intended.

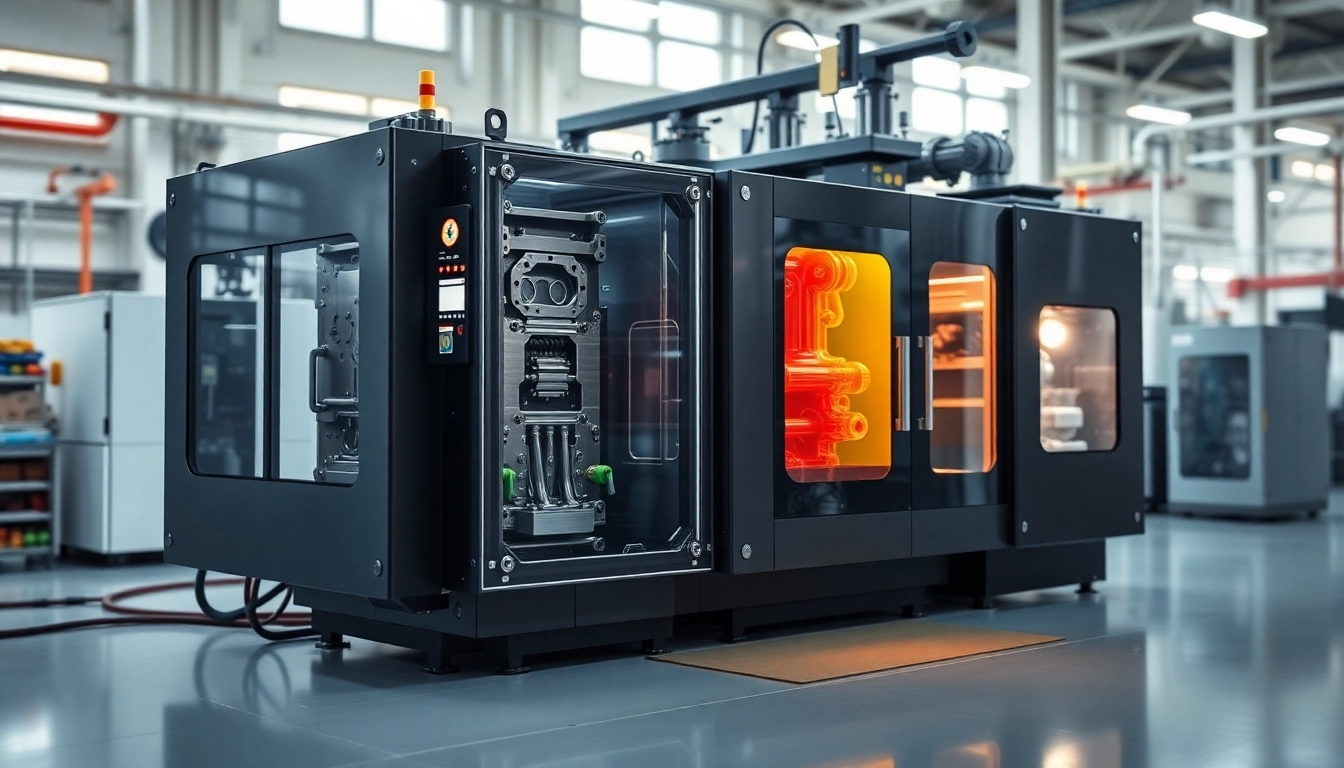

The Injection Molding Process

The injection molding process involves several key steps:

- Material Preparation: Raw plastic materials, typically in pellet form, are fed into a hopper and then heated to a molten state.

- Molding: The molten plastic is injected into a mold cavity through a nozzle at high pressure. The mold is designed to create the specific shape of the prototype.

- Cooling: Once the cavity is filled, the material is allowed to cool and solidify. This step is crucial as it affects the final part’s dimensional accuracy and strength.

- Demolding: After cooling, the mold is opened, and the prototype is ejected. Any excess material, known as flash, may need to be trimmed away.

- Finishing: The prototype may undergo additional processes such as painting, surface finishing, or assembly, depending on its intended use.

Key Benefits of Prototyping

Investing in injection molding prototypes offers numerous benefits:

- Cost Efficiency: Early detection of design flaws can reduce costs associated with mass production errors.

- Material Efficiency: Prototyping can help determine the most suitable materials for the final product, minimizing waste.

- Improved Design Validation: Physical prototypes provide tangible insights, allowing teams to test form, fit, and function more effectively than with digital models alone.

- Enhanced Collaboration: Engaging various stakeholders in the prototyping process fosters collaboration and ensures that all perspectives are considered before moving to production.

Choosing the Right Prototyping Method

Injection Molding vs. 3D Printing

Both injection molding and 3D printing have their pros and cons when it comes to prototyping. Injection molding is typically faster for producing larger quantities and results in higher durability and material consistency. In contrast, 3D printing allows for rapid iteration of designs and often requires less upfront investment.

When deciding between these methods, consider factors such as:

- Production Volume: If you need a large number of parts quickly, injection molding might be the way to go. For small batches or one-off designs, 3D printing is usually more efficient.

- Material Properties: If your prototype must simulate end-use conditions closely, injection molding may provide more realistic material properties.

- Design Complexity: 3D printing enables complex geometries that may be challenging to achieve with injection molding.

Material Selection for Prototypes

Choosing the right material for injection molding prototypes is crucial as it affects performance, durability, and overall cost. Common materials used include:

- ABS (Acrylonitrile Butadiene Styrene): Known for its toughness and impact resistance, making it suitable for functional testing.

- PP (Polypropylene): Offers excellent fatigue resistance and is often chosen for products requiring flexibility.

- POM (Polyoxymethylene): Highly suitable for precision parts due to its low friction and high wear resistance.

- PC (Polycarbonate): Ideal for prototypes needing high strength and transparency.

Evaluating Cost vs. Benefit

While injection molding prototypes can have a higher initial cost than 3D printing, the long-term benefits often outweigh the upfront expenses. Companies need to assess:

- The required precision and tolerance of the final product.

- The anticipated production volume after prototyping.

- The potential costs associated with design changes later in the production process.

A thorough cost-benefit analysis will help businesses determine the most efficient and effective approach for their specific needs.

Design Guidelines for Successful Prototyping

Optimal Design Features

Incorporating optimal design features is essential when creating effective injection molding prototypes. Key considerations include:

- Draft Angles: Implement draft angles of 1-3 degrees to facilitate easier demolding and prevent damage.

- Fillets and Radii: Adding fillets and rounded edges reduces stress concentration and enhances the prototype’s durability.

- Wall Thickness: Maintain uniform wall thickness (typically 1-3 mm) to ensure even cooling and prevent warping.

Common Design Missteps to Avoid

Avoiding common design pitfalls can make a significant difference in the success of prototypes:

- Ignoring Tolerances: Ensure that you specify appropriate tolerances in design to match the requirements of the injection molding process.

- Neglecting Assembly Considerations: Designs should facilitate easy assembly, considering parts positioning and connection methods.

- Overly Complex Designs: Keep designs straightforward to reduce potential complications during manufacturing and limit costs.

Best Practices for Enhanced Functionality

To enhance the functionality of injection molding prototypes, consider these best practices:

- Utilize Simulation Software: Employ simulation tools to predict how your prototypes will behave under real-world conditions, thus minimizing design errors.

- Iterate Based on Feedback: Gather input from engineers and potential users to refine your design iteratively.

- Test with End-Use Materials: Whenever feasible, use materials that mimic those intended for the final product to ground testing and enhance reliability.

Real-World Applications of Injection Molding Prototypes

Case Studies in Various Industries

Injection molding prototypes have proven invaluable across multiple sectors:

- Automotive: Companies leverage prototypes to design complex parts like dashboard components, ensuring safety and compliance while enhancing user experience.

- Consumer Electronics: Tech firms can rapidly prototype casings that house delicate components, addressing design challenges and aesthetic concerns.

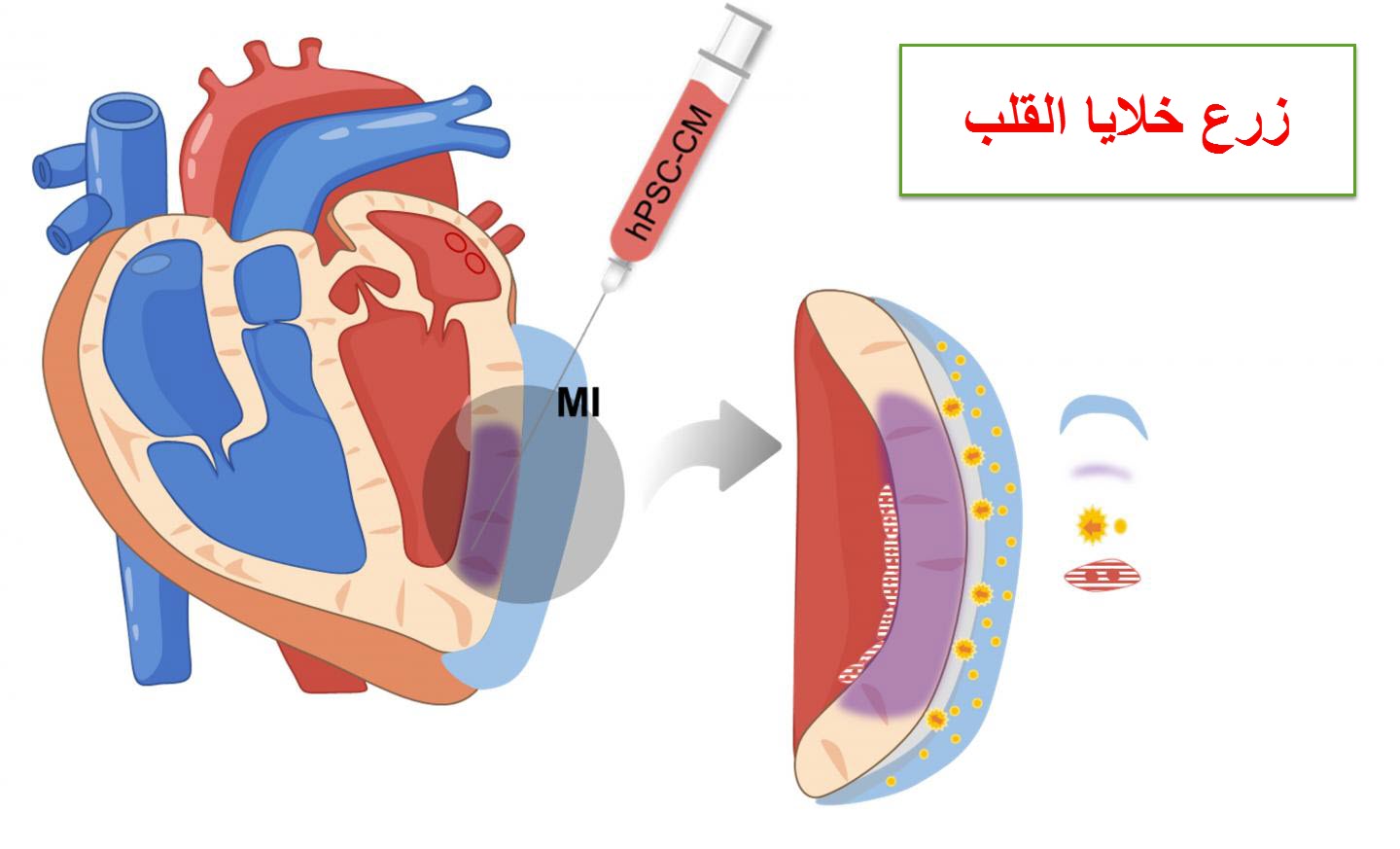

- Medical Devices: Prototyping is critical when developing devices that must meet stringent regulations and functional requirements.

Success Stories Highlighting ROI

Several organizations have successfully utilized injection molding prototypes, showcasing significant returns on investment:

- Company A: A startup producing kitchen appliances used prototypes to refine their product before launching and found a 20% reduction in time to market.

- Company B: A leading automotive manufacturer that utilized injection molding prototypes to perfect a new component design, resulting in projected cost savings of $2 million on manufacturing.

Innovative Uses Beyond Traditional Applications

Beyond traditional applications, companies are finding innovative uses for injection molding prototypes:

- Prototyping in the development of sustainable packaging solutions that reduce environmental impact while meeting consumer demands.

- Exploring the use of smart materials that can adapt to their environments, necessitating rapid prototyping to analyze designs under various conditions.

Future Trends in Injection Molding Prototyping

Technological Advancements to Watch

As the industry evolves, several technological advancements are emerging that could reshape injection molding prototyping:

- Automation and AI: Integrating automation can streamline the prototyping process, reducing lead times and enhancing precision.

- Advanced Materials: Researchers are discovering new composite materials that combine the benefits of plastics and metals, facilitating improved performance and versatility.

- 3D Molding Technology: Innovations in 3D printing for mold manufacturing may create opportunities for faster and more flexible prototyping cycles.

Eco-Friendly Materials in Prototyping

Growing awareness of sustainable practices is driving a shift toward eco-friendly materials in prototyping:

- Biodegradable Plastics: These materials provide alternatives that break down more efficiently, reducing long-term environmental impact.

- Recycled Materials: Utilizing recycled content can bolster sustainability efforts while still delivering functional prototypes.

Predictions for Industry Evolution

The injection molding prototyping landscape is poised for continued evolution, with the potential for:\n

- Increased collaboration among engineering and design teams globally, leveraging online platforms and digital twins.

- Heightened emphasis on customization, allowing users to create prototypes tailored to specific consumer needs.

Leave a Reply